The operational benchmark study for identifiers 937293009, 681167901, 8001231238, 952206608, 312345678, and 18669890547 presents an analytical overview of performance metrics within various sectors. It highlights significant variances in productivity levels when compared to established efficiency benchmarks. The findings suggest both strengths to leverage and weaknesses to address. Understanding these dynamics can lead to enhanced operational efficiency and continual growth, yet the path forward requires careful consideration of best practices and methodologies.

Overview of Key Identifiers

In the realm of operational benchmarking, key identifiers serve as critical metrics that enable organizations to assess their performance relative to industry standards.

Identifier significance lies in their ability to highlight areas of strength and weakness, influencing operational impact.

Performance Metrics Analysis

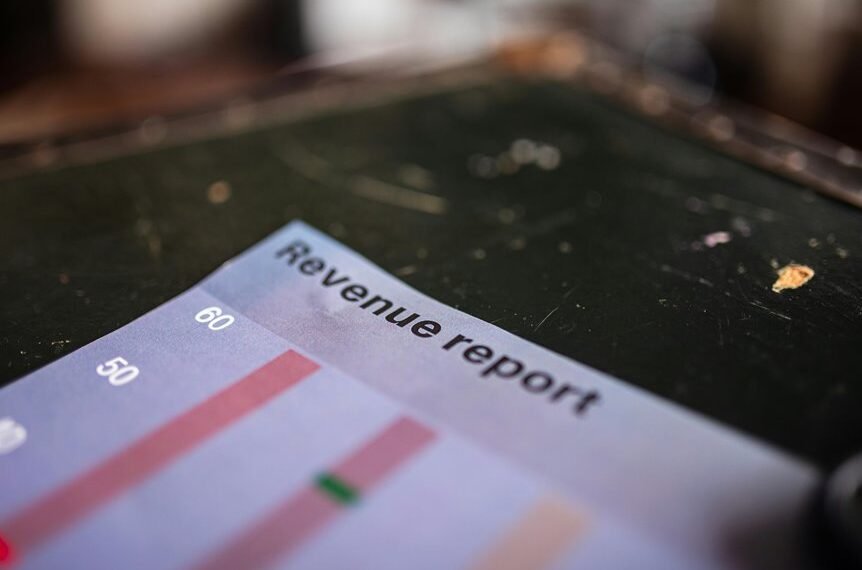

While organizations strive for operational excellence, the analysis of performance metrics emerges as a cornerstone for informed decision-making.

Performance indicators and efficiency metrics provide critical insights into operational effectiveness. By systematically evaluating these metrics, organizations can identify areas for improvement, streamline processes, and enhance overall performance.

This analytical approach empowers decision-makers to allocate resources more effectively, fostering an environment conducive to continuous growth and innovation.

Productivity Levels Comparison

When organizations engage in a productivity levels comparison, they uncover vital distinctions that can significantly influence operational strategies.

Analyzing productivity trends against established efficiency benchmarks reveals discrepancies among entities. These insights enable businesses to identify areas for improvement and adapt their approaches accordingly.

Best Practices for Operational Efficiency

Identifying productivity discrepancies among organizations naturally leads to the exploration of best practices for operational efficiency.

Implementing lean methodologies facilitates the elimination of waste, fostering a culture of continuous improvement.

Process optimization techniques, such as workflow analysis and performance metrics, further enhance productivity.

Conclusion

In conclusion, the operational benchmark study reveals that while significant discrepancies in performance metrics exist, the path to improvement appears deceptively straightforward. It is ironic that organizations often overlook the very best practices they champion, opting instead for complex solutions to simple problems. Embracing lean methodologies and fostering a culture of continuous improvement may seem like a daunting task, yet it is precisely this commitment to simplicity that could unlock their true potential for operational efficiency and growth.